From New Zealand to the world

Keratin proteins are the building blocks of life and are vital to the biology and physiology of every animal on our planet.

Keratin is the key structural material making up hair, wool, feathers, nails, horns and the outer layer of skin. It protects the surfaces of internal organs from damage or stress, and it is one of the toughest biological materials in the world.

Keratins play a physical role in maintaining cell structure as well as a biological role helping cells make a range of essential proteins for healthy skin structure.

Chinese herbalists have known about the beneficial properties of keratin for over 500 years, using a substance made from the ground ash of human hair to heal wounds and clot blood. But it wasn’t until the 1930s that scientists demonstrated that there are actually many different types of keratin, with different molecular weights and different properties.

At Keraplast, we unlock the power of keratin proteins from regeneratively grown wool so that these can be redeployed as beneficial bioactive ingredients. Our proprietary Functional Keratin® technology platform has evolved from decades of scientific research, including over 20 years of fundamental and applied keratin science. We have the technological capability to accurately and skillfully recover a range of specific keratin proteins, with specific molecular weights, that have specific beneficial properties.

We are world experts in bioactive keratin recovery and formulation.

At Keraplast, we gently recover specific keratin proteins using tightly controlled and targeted processes. Our Functional Keratin® technology platform enables us to recover differentiated, soluble, bioactive keratin proteins with well defined molecular weights, and with their bioactivity intact.

Most keratin proteins are “dual-helix” in structure. These helices are held together by strong covalent (and other) bonds. Keraplast isolates individual keratin proteins (all at industrial levels of production) and cleaves those chemical bonds creating individual protein strands which are then stabilised. This has the impact of both solubilising the protein and releasing the amazing bioactivity available in this incredible protein.

The core differentiator of keratin is the amino acid cystine. Most common methods of keratin production aggressively hydrolyse complete keratin proteins often destroying the cystine as part of the process. These production methods ensure the complete bioactivity remains unavailable to consumers.

To sum it up: Our patent protected technology enables us to recover soluble, bioactive keratin proteins from wool fibres while still controlling the protein molecular weight and cystine availability. Our proteins are then blended together to create ingredients that are 91% homologous (or similar) to human keratin.

We understand and respect the different roles that keratins play in the body, and we isolate each of these types of keratins separately.

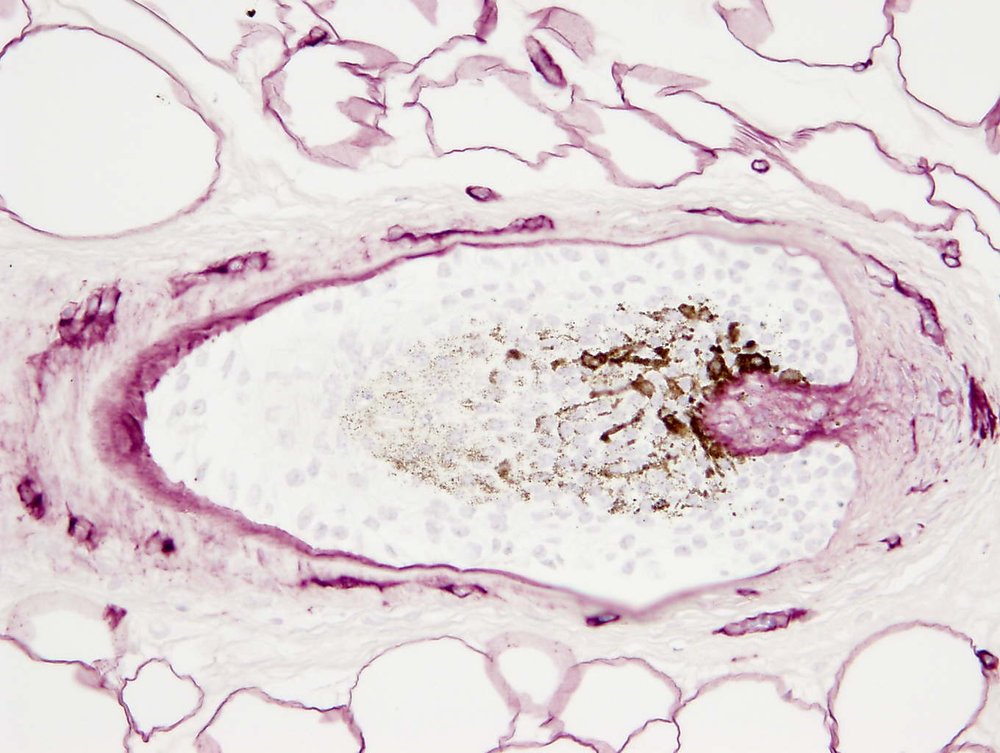

For example, some Functional Keratin® formulations incorporate keratin intermediate filament proteins. When applied to skin, hair follicles or taken internally these proteins encourage skin cells to make more of the essential proteins needed for healthy skin structure and repair, in particular the collagen IV and collagen VII responsible for the strong dermal-epidermal junction that becomes weakened during the aging process.

In hair, these proteins repair hair strength by rebuilding damaged keratin intermediate filaments within the fibre. These different keratin types and functions are not differentiated within traditional production methods which treat all keratins the same. Damaged hair can require repair inside the cuticle so Keraplast has developed a small peptide that can get into the hair cortex and bind covalently to broken di-sulfide bonds inside the hair.

This unique process of solublising whole keratin proteins and then stabilising them enables Keraplast’s formulations to remain bioactive within the human body, capable of bonding to human hair or skin to provide a natural protective film and stimulating collagen production.

Keraplast uses natural raw materials that are sustainably produced by the world’s best managed agricultural sector. Wool is a 100% natural, fully renewable fibre and it is produced year-round by a range of animals, including sheep. Crossbred sheep, such as Romney and Perendale, are the most common breeds in New Zealand and they do not naturally shed their wool. This can be uncomfortable for the animals during the long, hot Summer, so these sheep are usually shorn once a year to avoid having to carry a full fleece of wool in the heat.

We harvest our wool from pasture-grazed sheep that are raised in the pristine countryside of New Zealand. The wool is harvested quickly and painlessly by using electronic clippers in much the same way as getting a haircut. A professional shearer can shear a sheep in less than two minutes. The wool is then collected into bales after the sheep have been shorn, and the sheep return to the pastures where they continue to graze and raise their young. During Autumn/Fall the thick fleece of wool regrows and keeps the sheep warm for the coming Winter.

We are on our journey to becoming a regenerative business and we have committed to ensuring that all of our wool is traceable back to individual farms and sustainable wool growers, all located within New Zealand’s biosecurity zone.

New Zealand is an island nation sandwiched between by the vast, rugged, South Pacific Ocean and the Tasman Sea. This incredible “moat” acts as a natural barrier to pests and diseases, and these natural barriers have been strengthened over time through modern technologies and protocols. New Zealand is now globally recognised as an exemplar for modern biosecurity systems, and this provides us with world-class biosecurity status as a source of natural materials.

Our wool is traceable back to our source farms, and this enables us to maintain high levels of quality and safety and ensures supply chain visibility. We value our partnerships with our farmers: we have walked their farms together and we know each of them by name. We know that wool is a natural product that is damaged by photo-oxidation when it is exposed to harsh sunlight. So, our farmers follow Keraplast’s strict wool harvesting protocols to ensure the wool is harvested at just the right time, and in just the right way, to produce the highest quality raw ingredients possible.

We are a global exporter, and we have strong partnerships with Croda International, AIDP Inc and IFF Health. Through these partnerships, our life changing ingredients have achieved global reach and are enhancing the wellbeing of millions of people.

Our research and development programmes are conducted in collaboration with New Zealand’s leading scientific organisations and innovators. Our research partners include AgResearch, the largest agricultural research organisation in New Zealand, and New Zealand’s Innovation Agency, Callaghan Innovation.

We are also extremely proud to partner with regenerative famers throughout New Zealand.